\ 首頁 ・產品應用・成型機

PCB成型機

特點

大量科技成型機採用PC-Base控制器及應用自行開發之控制軟體,依機型z軸可進行各軸獨立或同步昇降,並可依需求增加跨軸成型功能,配備有多國專利自動脫料裝置,機種分單 、雙、4、5、6主軸,各軸自動換刀。

多元應用

應用於光模塊、mini LED、半導體治具加工、手機硬板、軟硬複合板、BGA載板,適合打樣、小批量及大批量生產,並可加裝定位尺執行深控成型或盲撈作業。

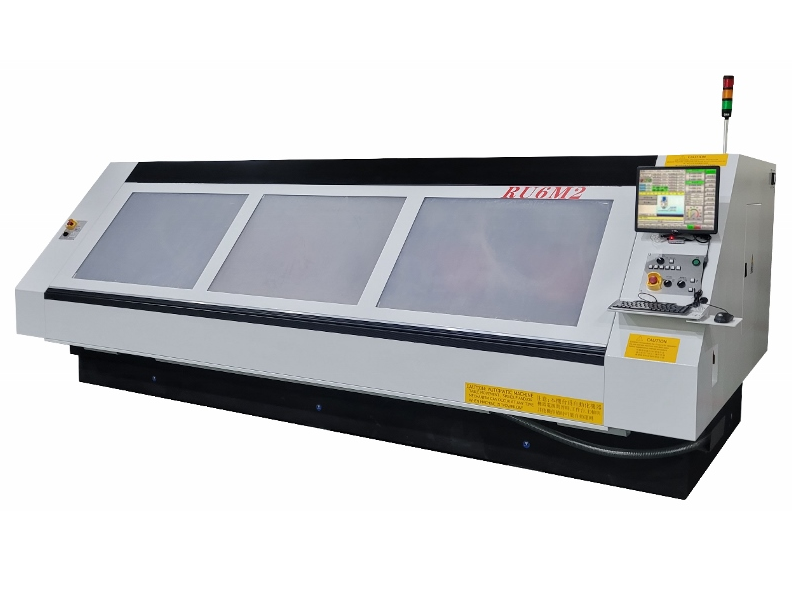

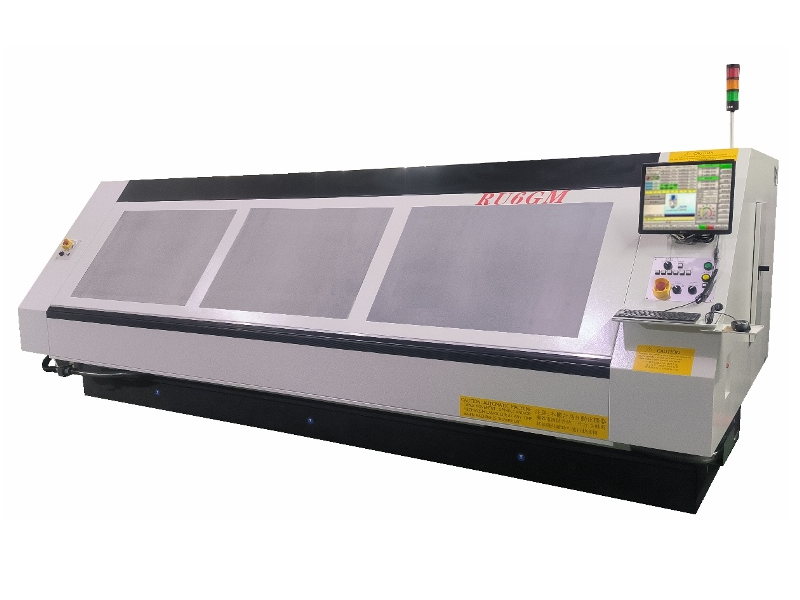

PCB成型機 標準系列

| ● | Z軸同時控制,適合打樣、小批量及大量生產使用。 |

| ● | 主軸軸數:單軸、2軸、4軸、5軸、6軸。 |

| ● | 配備自動脫料裝置並搭配自動選PIN孔程式。 |

| ● | 可選配支援MES通訊、設備即時監控系統。 |

PCB成型機 深度控制系列

| ● | 主軸軸數:單軸、2軸、4軸、5軸、6軸。 |

| ● | Z軸獨立控制,配備Z軸定位尺及板厚偵測尺,可執行深度控制補償。 |

| ● | 配備真空吸盤+自動頂出裝置,上下料快速,克服板材彎曲。 |

| ● | 具備加工後,深度自主檢測功能,確保加工後深度品質。 |

PCB成型機 CCD深控系列

| ● | 主軸軸數:單軸、2軸、5軸、6軸。 |

| ● | Z軸獨立控制,配備Z軸定位尺及板厚偵測尺,可執行深度控制補償。 |

| ● | 配備真空吸盤裝置,上下料快速,克服板材彎曲。 |

| ● | CCD對位補正功能,有效補正實際板材誤差量。 |

| ● | 適用PCB光模塊、mini LED、精密對位加工產品。 |